Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Nowadays, the market is bursting with various wireless chargers, and ordinary consumers may find it difficult to judge the quality of these products. Usually, they can only choose their preferred product based on its brand or other customers’ feedbacks. As a professional wireless charger manufacturer, how do we evaluate the quality of a charger? Below, we analyzed which wireless charger is better from a professional perspective.

The core component of the wireless charger is its chipset. We tested two chargers with different chipset, one is the MCU chipset and the other is the IP6808 chipset. The two look similar in appearance, but the charging processes of the two are significantly different.

The followings are the performances of the charging process of the two chargers, both of the charging object s are the Apple iPhone 12 with a 10% battery level.

Charging Process of the MCU Chipset

Firstly, let’s observe the entire charging process of the MCU Chipset. In our testing, we monitored the input voltage and current of the charger. The horizontal axis in the figure represents the time axis of charging duration, the left vertical axis represents the voltage of the charger (corresponding to the green line), and the right vertical axis represents the current of the charger (corresponding to the pink line). The battery of the iPhone tested this time has not been fully discharged, with 10% remaining, so this charging process has not gone through the Pre-charge stage.

The charging time from 10% to 100% was 4 hours and 16 minutes, and there were mainly four stages during this period.

The first stage ranges from 0:00 to around 1:25. At the beginning of charging, the input voltage of the charger is 9.0V and the input current is about 0.7A. After a few minutes, the current rises to 0.8A and fluctuates around 0.8A to 0.85A.

The second stage ranges from 1:25 to 1:55. The input voltage of the charger is still 9.0V, while the current gradually decreases from 1:25 to around 0.42A, fluctuating up and down at this position. It is because the phone detects that the temperature of the charger is too high, so the power of the charger is reduced. Usually, the protection temperature of the phone itself is between 45°C and 50°C.

The third stage ranges from 1:55 to 3:32. This stage is mainly characterized by sharp fluctuations in charging voltage and current, with the voltage switching back and forth between 9V and 5V, and the current switching back and forth between 0.17A and 0.85A. Sometimes, the instantaneous current can reach 1.07A. This is because the charger has detected that its temperature is too high, so it has also started adjusting the charging power. The protection temperature of the MCU charger is 80°C.

The fourth stage is from 3:32 to 4:16 (charging end). In this stage, the voltage is basically maintained at 9V and drops to 5V near the end of charging; The current gradually decreases from 0.6A to 0.2A, and as it approaches the end, it fluctuates between 0.2A and 0.0A, ultimately ending this charge. In this trickle stage, the iPhone’s battery is charged from 80% to 100%.

In summary, the root cause of the aforementioned charging process is the poor heat dissipation performance of the MCU chipset. During the charging process, the charger not only wants to complete the task of charging the phone as soon as possible, but also has to control its own high temperature. Therefore, switching back and forth between high and low power is detrimental to the phone’s battery.

Charging Process of the IP6808 Chipset

Charging with the IP6808 chipset charger, it took only 3 hours and 20 minutes to charge from 10% to 100%. During this period, four stages were mainly observed. Since the charging voltage remains at 9V throughout the entire charging process, the following stage descriptions will not repeat the charging voltage.

In the first stage from 0:00 to 0:07, the wireless charger detected the battery of iPhone remains a 10% level and did not require a trickle charging stage, so it directly applied a higher current of 1.15A for charging. The reason why the Trickle charging process was skipped was that the cell phone battery voltage during Trickle charging is generally 0~2.75v, while when the cell phone battery has 10% level, the battery voltage is about 3V, which can be charged directly with high current without damaging to the battery.

The second stage is from 0:07 to 1:30. The charger detected the voltage of iPhone battery was gradually rising, and decreased the current to 0.8A and then fluctuates between 0.8A and 1A to charge the phone. In the end of this stage, the battery was charged to 60%.

The third stage, from 1:30 to 2:31. The charger detected that its temperature had reached 55 degrees and activated the protection mode to prevent further temperature rise. At this point, the charger started reducing its power output. However, to continue charging the phone battery at this voltage, it gradually decreased the charging current from 1.0A to around 0.25A. In the end of the third stage, the battery was charged to 80%.

Stage 4, from 2:31 to 3:32. The charger detected that the battery voltage had reached 4.35V and switched to trickle charging mode. Apple phone batteries use high-voltage cells with a maximum voltage of 4.35V. During this stage, the charger applied a low current of 0.15A to slowly charge the phone until the battery was fully charged.

Conclusion

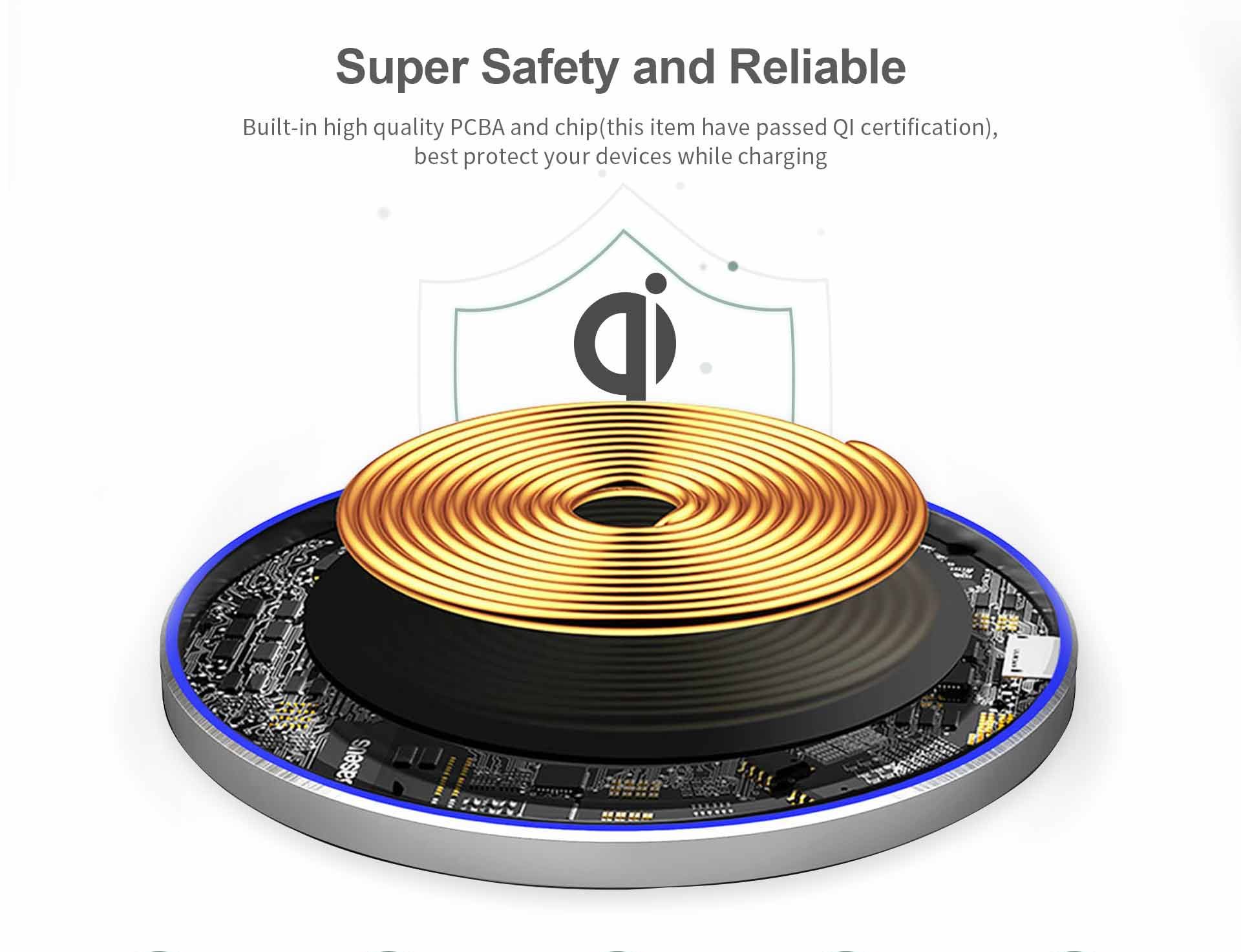

By comparing the charging processes of the two chargers, we can see that the IP6808 chipset charger maintained stable charging voltage and current throughout the charging process, had lower charger temperature, and shorter charging time. On the contrary, the MCU chipset charger exhibited unstable charging voltage and current, switched between high and low charging power to control its own temperature, and had a longer charging time, especially when the temperature reaches 80 degrees. Therefore, using the IP6808 chipset with QI-Certified is the preferred choice for producing our high-quality wireless chargers.